|

Product Research and Development

I started my dream job at Naked Prosthetics in March 2019 as a Mechanical Engineer responsible for research and development of new products. I was responsible for- Taking the Griplock Finger (GLF) through design, research, prototyping, product testing, part drawings, vendor relations, manufacturing, bill of materials, beta testing and production. DFMA. Created detailed documentation and assembly manuals for production as well as serialization systems. Created tooling to reduce assembly time from 40 minutes to under 15 minutes. Product Testing through static load testing, fatigue testing and life-cycle testing. Invention and Product Development of Alignment Jig: Invented a patent-able tool to ensure proper mounting of GLF on sockets irrespective of hand size. Created Dummy Fingers to visualize prosthetic position before installation. Created a system in Solidworks to check GLF sizes easily against patient photographs for customer care recommendations as well as tutorials for clinicians. |

|

|

Mechanical Engineering at Technifex

During the Fall of 2018 I was offered a position to design practical special effects for theme park rides at Technifex (Valencia, CA). I spent six months working on a secret water ride for a massive Asian theme park. |

|

|

Internship at Humotech

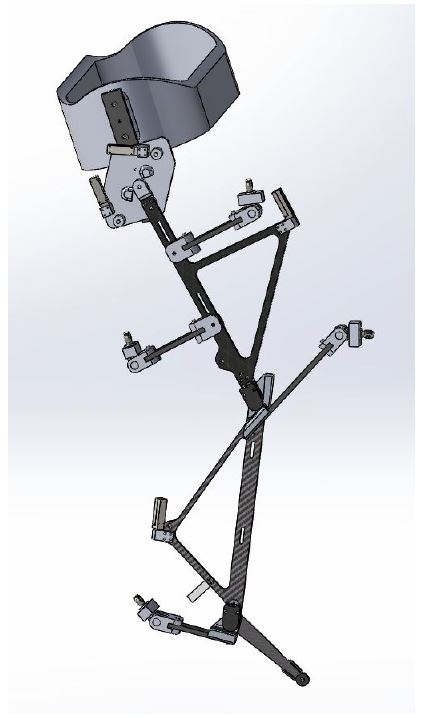

In the summer of 2016, I was made project manager of developing a hip-knee-ankle exoskeleton for Human Motion Technologies, a startup born of the Experimental Biomechatronics Lab at Carnegie Mellon University that develops technology in the field of prostheses and exoskeletons. Here you can see me test out a prototype for them back in 2015 at an innovation fair! The image next to it is an early conceptual CAD work in SolidWorks.

|

|

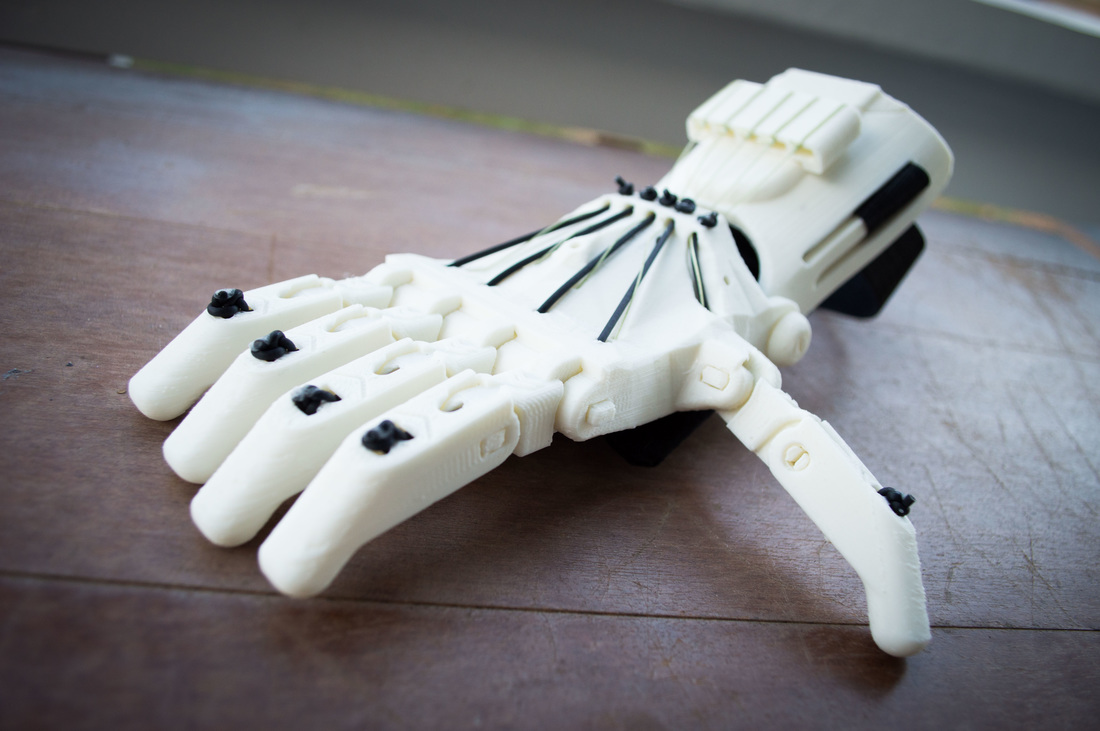

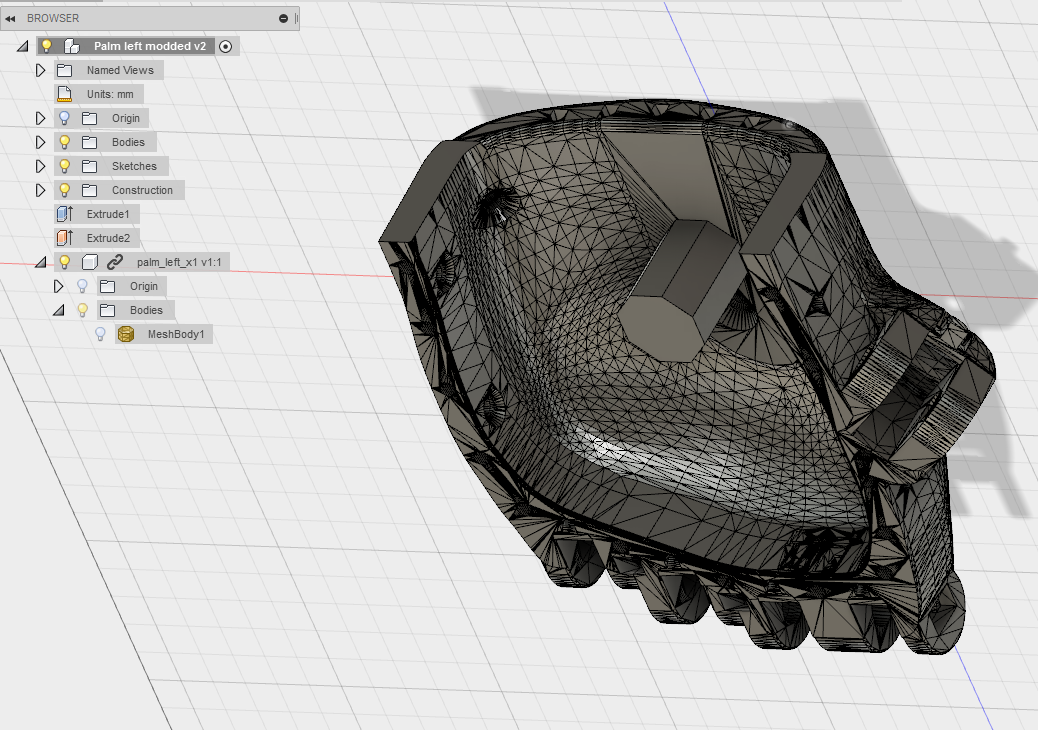

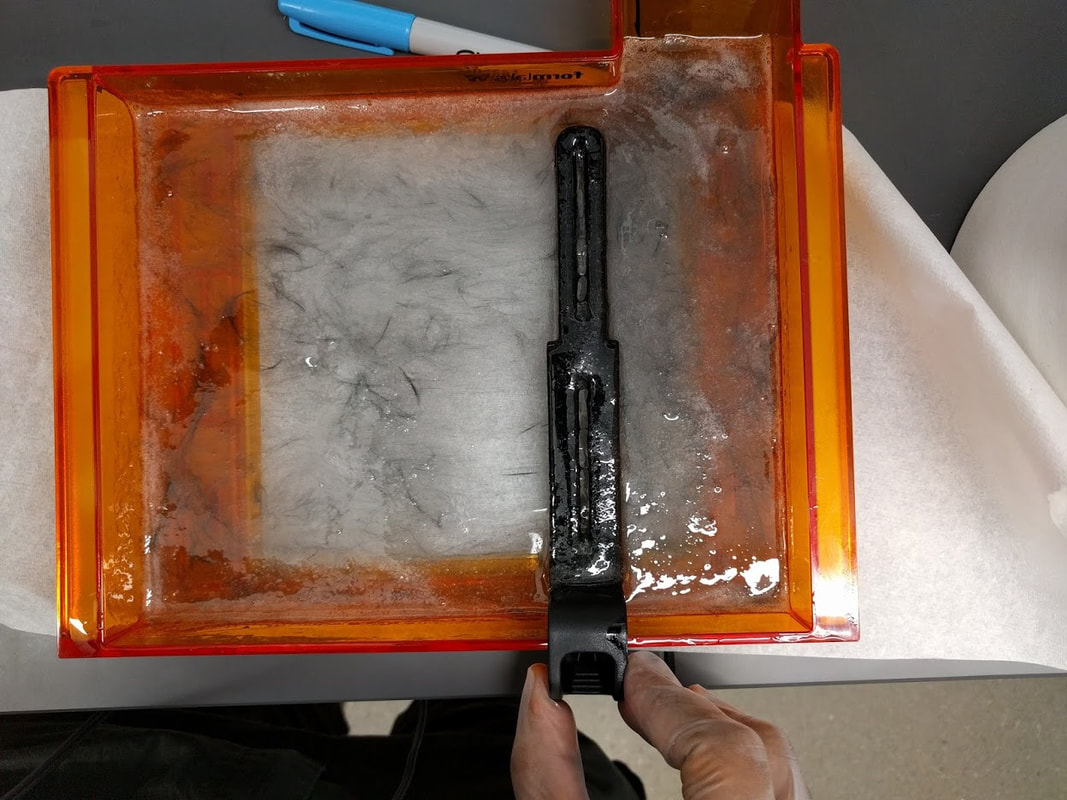

Research at CMU

During the summer and fall of 2016, I also worked as a Research Assistant in the Human-Computer Interaction Institute at Carnegie Mellon University, leading mechanical design and prototyping modular prostheses for upper limb amputees, while working closely with the E-Nable community, under the guidance of Jen Mankoff and Scott Hudson. http://www.digitaltrends.com/cool-tech/carnegie-mellon-3d-printed-prosthetics/ In 2017, I experimented with 3D printing of composite materials to make artificial bone. Here's an image of carbon fiber mixed in resin in the print tank of a FormLabs printer. https://www.3ders.org/articles/20160803-3d-printed-medical-phantom-models-are-advancing-training-for-clubfoot-treatments.html |

|

Mechatronics Project

As a part of the coursework of Carnegie Mellon University's "Mechatronic Design", my team made an automated trash sorting robot called TrashE over the Spring semester of 2016. This involved about 20 hours of work a week, and I contributed in the mechanical design and manufacturing as well as website maintenance. The bot sorts 15 different items of trash into 4 separate categories in under 45 seconds with at least 85% accuracy. Take a look at a fun video I made introducing it. For more details, visit our project page! |

|

|

Prosthetics Workshop

As a part of a Summer Boot Camp at Next Step Bionics & Prosthetics, I learnt about prostheses and orthotic devices- right from dealing with plaster, to create sockets and braces to adjusting prosthetic feet, to working with myoelectric devices and robotic arms! |

|

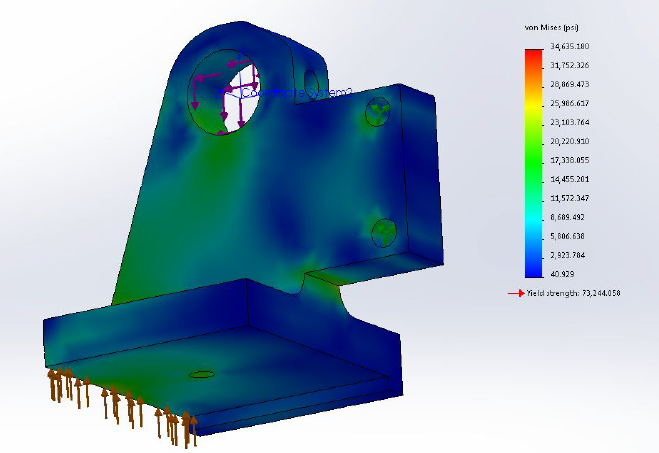

During the summer of 2018, I participated in a design challenge to create a conceptual design for a spinal implant inserter, which I completed in 3 days.

|

|